Synthetic chrysoberyl – HDSM

The mineral or gemstone chrysoberyl is an aluminate of beryllium with the formula BeAl2O4.

Buy natural gemstones in our gem shop

The name chrysoberyl comes from the Greek words chrysos and beryllos. Meaning “a gold-white spar”. Despite the similarity of their names, chrysoberyl and beryl are two completely different gemstones. Although they both contain beryllium. Chrysoberyl is the third-hardest frequently encountered natural gemstone. And lies at 8.5 on the Mohs scale of mineral hardness.

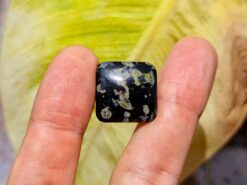

Ordinary chrysoberyl is yellowish-green and transparent to translucent. When the mineral exhibits good pale green to yellow color and is transparent, then it consider as a gemstone quality. The three main varieties of chrysoberyl are: ordinary yellow-to-green chrysoberyl, cat’s eye or cymophane, and alexandrite.

Yellow-green chrysoberyl was referred to as “chrysolite” during the Victorian and Edwardian eras. Which caused confusion since that name has also been used for the mineral peridot as a gemstone. That name is no longer used in the gemological nomenclature.

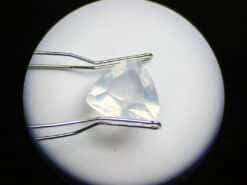

Bagdasarov modification (HDSM)

Synthetic chrysoberyl “Horizontal directional solidification method” created by Kh.S.Bagdasarov in 1964 was new radical idea of single crystal growth based on moving a crucible with the raw material and a single crystal seed in the horizontal direction.

This method was created for the growth of large-size, Nd doped, high-perfect yttrium-aluminum garnet laser crystals. It turned out to be very efficient for stone growth too creating crystals with previously unseen surface areas. Using the HDS method issues of synthesis of large and especially large plate-form refractory leucosapphire single crystals were solved.

The synthetic chrysoberyl HDS methods growth process consist of the following process’s

Seed (with any require crystal orientation) is installed at the front tip of the container which resembles a ship in a horizontal position.

The raw stone material is placed in the container.

The container is placed into a furnace.

The growth process is done in a vaccum or inert atmosphere.

During the growth process via a camera which is located on the top of the furnace, the process is being followed and diagnosed during the full duration of the growth process.

The melt is then slowly cooled.

This method makes it possible to get large slabs with almost perfect edges and of any given crystallographic orientation: C-plane, M-plane, R-plane or A-plane.

Synthetic chrysoberyl Bagdasarov stones has a very high optical quality and is suitable for very demanding optical, mechanical, RF and LED applications.

The HDSM method allows to carry out repeated crystallization in case when additional chemical purification of the raw material is required. It is also possible to carry out a continuous crystallization process by directed shift of the crucible echelon through the crystallization zone.

While realizing the HDSM method it is technically easy to create a controlled temperature field that is extremely necessary for growth of high-perfect large-size single crystals. This method makes it possible to get large slabs with almost perfect edges and of any given crystallographic orientation.

Synthetic Chrysoberyl – HDSM

Chemical formula: BeAl2O4:Cr3+

Crystal system: Rhombic

Hardness (Mohs): 8.5

Density: 3.7

Refractive index: 1.741-1.75

Dispersion: 0.015

Inclusions: Inclusions free. (key separation from natural chrysoberyl: Fogs, cracks, holes, multi-phase

inclusions, quartz, biotite, fluorite)