Strontium titanate

Buy natural gemstones in our gem shop

Fabulite Strontium Titanate: A Unique Synthetic Gemstone

Synthetic strontium titanate is a fascinating material that was one of several titanates developed during the late 1940s and early 1950s. It was among a group that also included barium titanate and calcium titanate.

History and Development

Research efforts were largely conducted at the National Lead Company (later known as NL Industries) in the United States, primarily led by Leon Merker and Langtry E. Lynd. On February 10, 1953, Merker and Lynd patented the initial growth process, and over the next four years, they patented several modifications, including adjustments to the feed powder and the use of coloring dopants.

Growth Process

The preferred method for growing synthetic strontium titanate is a variation of the Verneuil process, also known as the flame-fusion process. An inverted oxy-hydrogen blowpipe is used for this growth, with feed powder combined with oxygen fed through the blowpipe. This process is further enhanced by introducing a third pipe that delivers additional oxygen, resulting in what is known as a tricone burner.

Importance of Oxygen

The introduction of extra oxygen is crucial for the successful synthesis of strontium titanate, as it ensures complete oxidation of the titanium component. The required ratio is approximately 1.5 volumes of hydrogen for each volume of oxygen.

Feed Powder Preparation

The feed powder used in this process is produced by first creating titanyl double oxalate salt (SrTiO(C2O4)2·2H2O) by reacting strontium chloride (SrCl2) and oxalic acid ((COOH)2·2H2O) with titanium tetrachloride (TiCl4). After washing to eliminate chloride, the material is heated to 1000°C to produce a free-flowing granular powder, which is subsequently ground and sieved to achieve particle sizes between 0.2 and 0.5 micrometers.

Crystal Growth

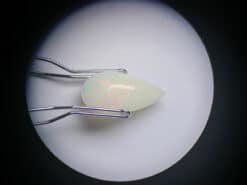

Once the feed powder is prepared, it is carefully dropped through the oxyhydrogen flame, melts, and falls onto a rotating and slowly descending pedestal beneath. The height of the pedestal is constantly adjusted to keep its top in the ideal position under the flame. After several hours, the molten powder cools and crystallizes into a single boule crystal with a unique, pedunculated pear shape.

Annealing Process

This boule typically measures up to 2.5 centimeters in diameter and 10 centimeters in length, and initially appears opaque black. To render it colorless and relieve any internal strain, the boule undergoes further annealing in an oxidizing atmosphere at temperatures exceeding 1000°C for 12 hours.

Thin Film Growth Techniques

In addition to its crystal growth, thin films of strontium titanate (SrTiO3) can be created by using various advanced techniques such as pulsed laser deposition, molecular beam epitaxy, RF sputtering, and atomic layer deposition. Each method results in thin films with different levels of crystalline quality, defect densities, and impurity content. These variations significantly impact the electronic and optical properties of the material, making it a versatile substance for numerous technological applications.

Strontium Titanate vs Diamond: The Ultimate Diamond Simulant?

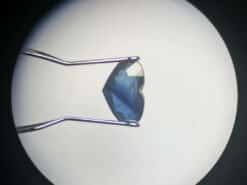

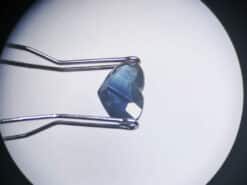

Due to its cubic crystal structure and high dispersion, synthetic strontium titanate was initially considered an excellent diamond simulant. Beginning around 1955, large quantities of strontium titanate were produced specifically to simulate diamonds.

Comparison with Synthetic Rutile

At the time, strontium titanate competed with synthetic rutile (commonly known as “titania”), with the primary advantage of strontium titanate being its lack of the yellowish tint and strong birefringence characteristic of rutile. While strontium titanate was softer than diamond, it had a superior optical resemblance to diamond, making it an attractive alternative for jewelry.

Emergence of New Simulants

Eventually, however, strontium titanate and synthetic rutile were both surpassed by newer diamond simulants, first by yttrium aluminum garnet (YAG) and later by gadolinium gallium garnet (GGG). The emergence of cubic zirconia as a diamond simulant marked a turning point, as it offered an even closer resemblance to diamond and was more cost-effective, quickly becoming the industry standard.

Modern Use and Collectibility

Despite being largely supplanted by newer materials, strontium titanate continues to be produced and is occasionally found in jewelry today. It remains one of the most expensive diamond simulants, and collectors may pay a premium for larger specimens exceeding 2 carats (400 mg). As a simulant, strontium titanate can be particularly deceptive when mixed with melee (i.e., stones smaller than 0.20 carats or 40 mg) or when used as the base material for a composite or doublet stone, with another material such as synthetic corundum as the crown or upper layer.

Identification Techniques

Under microscopic examination, gemologists can distinguish strontium titanate from diamond by several characteristics. Strontium titanate’s relative softness is often evident through surface abrasions, and its excessive dispersion can be recognized by trained eyes. Additionally, remnants of the synthesis process, such as occasional gas bubbles, are a telltale sign. Doublets can also be identified by observing a join line at the girdle, which is the “waist” of the stone, or by detecting flattened air bubbles or adhesive used at the bonding point.

Strontium titanate

Strontium Titanate Mohs Hardness

Strontium titanate has a Mohs hardness of 5 to 6, making it significantly softer than diamond, which has a hardness of 10.

Implications for Jewelry

This property makes strontium titanate susceptible to scratches and abrasions, meaning it requires careful handling, especially when set in jewelry that is worn regularly. Its softness, combined with its dazzling optical properties, makes strontium titanate an interesting choice for collectors and those who appreciate unique and vintage gemstone alternatives.

Historical Significance

While strontium titanate is no longer a mainstream choice for diamond simulants, its history, optical properties, and rarity give it a special place in the world of gemstones. It is a beautiful example of mid-20th-century scientific ingenuity, with its dazzling brilliance and vibrant dispersion continuing to captivate those fortunate enough to encounter it.

Frequently Asked Questions (FAQ)

1. What is strontium titanate used for?

Strontium titanate is primarily used as a diamond simulant in jewelry, particularly in the mid-20th century. It has also been used in various technological applications due to its optical and electronic properties, such as in thin films for research and development.

2. How is strontium titanate different from diamond?

Strontium titanate differs from diamond in several ways, including its lower hardness (Mohs 5-6 compared to diamond’s 10) and higher dispersion, which gives it a distinct fire. It is also a synthetic material, whereas diamonds are naturally occurring.

3. Is strontium titanate still used in jewelry today?

While it has largely been replaced by other diamond simulants like cubic zirconia, strontium titanate is still occasionally used in jewelry today. It remains popular among collectors and those who appreciate vintage and unique gemstones.

4. How can gemologists identify strontium titanate?

Gemologists can identify strontium titanate by its softness, surface abrasions, high dispersion, and the presence of gas bubbles from the synthesis process. Additionally, doublets can be identified by join lines or bubbles at bonding points.

5. What are the growth methods for strontium titanate thin films?

Thin films of strontium titanate can be grown using various techniques, including pulsed laser deposition, molecular beam epitaxy, RF sputtering, and atomic layer deposition. These methods impact the material’s crystalline quality and properties, making it suitable for different technological applications.